Our goal is to find the best solutions in the minimum possible time, for this there is continuous contact with customers, so that the mould is designed with the design and specifications required by the client.

We have a professional and dedicated team that uses cutting edge technology to manufacture your moulds with the best quality. We constantly supervise the production of the moulds according to the requirements and specifications of the customers, to meet the agreed delivery time and guarantee their total satisfaction. This supervision is complemented by sending a weekly progress report, with updated information, graphics and photos, of the state of development of each project.

The company’s Quality Management System complies with all requirements within the scope of the following operations: steel reception, 2D / 3D drawing / design, production, testing, final inspection, after-sales service and administration.

Quality assurance, control and monitoring procedures are integrated into all production processes in the company.

In addition, our quality control team is at the customer’s disposal to respond to their own specific requirements in order to ensure their implementation.

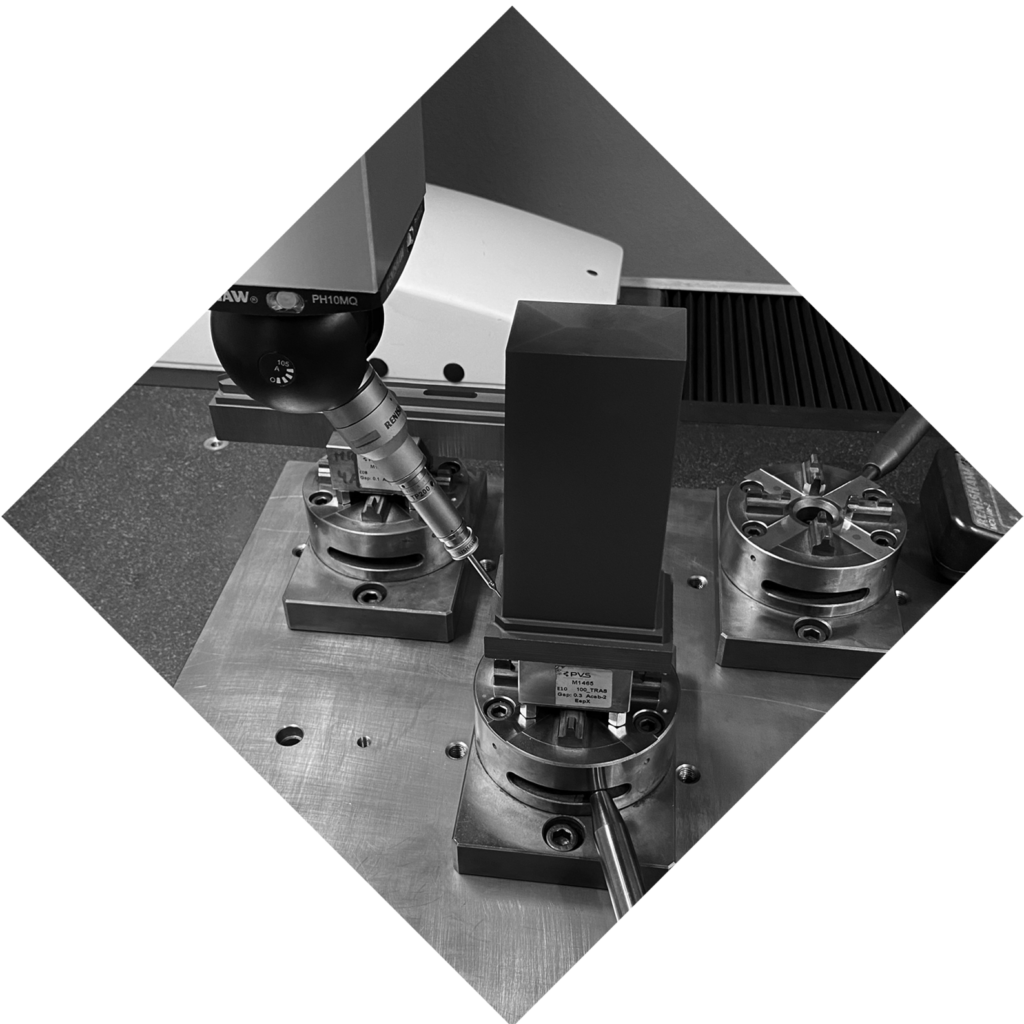

Within our quality department we also have a wide range of measuring equipment calibrated according to standards, including a coordinate measuring machine (CMM) and 2 optical measuring machines (GOM and STEINBICHLER) for accurate dimensional reports of parts produced with tight tolerances and still with reverse engineering capability.

After acceptance / approval by the customer, the preparation for shipment is made in a very thorough manner.

The mould is prepared according to the client’s specifications, and furthermore it is accompanied by the following elements:

· steel certificate / heat treatment certificate

· 2D / 3D project on paper and digital

· trial report / dimensional report

· mold-flow study

· recommended maintenance plan

· injection system information, if applicable

After the shipment, PVS Moldes ensures an after-sales service, always providing customer support since modifications, repairs, maintenance, among others.

© 2020 PVS Portugal. All Rights Reserved. | General Terms and Conditions of Purchase | Designed by Blink Eye

#1 Is the injection at the most advisable / appropriate location?

#2 Was a complete mold-flow study done?

#3 Is the ejection the most suitable to eject the plastic parts freely, without marks or warps?

#4 Is the type of cooling the most suitable and its location is the most acceptable to achieve a quick cycle and without the part being damaged and not causing weak points in the steel?

#5 When the mould opens, do the parts remain on the ejection side?

#6 Is the ejection stroke sufficient to release the plastic parts?

#7 The parts to be moulded have sufficient draft angles for a good demoulding?

#8 Are cavities and cores strong enough to not yield to injection pressures?

#9 Is the mould size suitable for the injection machine and ensured that the mould fits between its columns?

#10 Are all its components standard and comply with the client’s specifications?

#11 If there are mechanical, hydraulic, or pneumatic sliders, do they have enough stroke to release the plastic parts?

#12 Is there a moulding area outside the plates of the injection machine, in case of off-center injection?

#13 Should the cooling / heating inlets and outlets be clear of the machine columns and whenever possible to the opposite side of the operator or downwards?

#14 When ejectors interfere with slider elements, are there microswitches to guarantee their recession before they close?

#15 Is the gas venting well positioned?

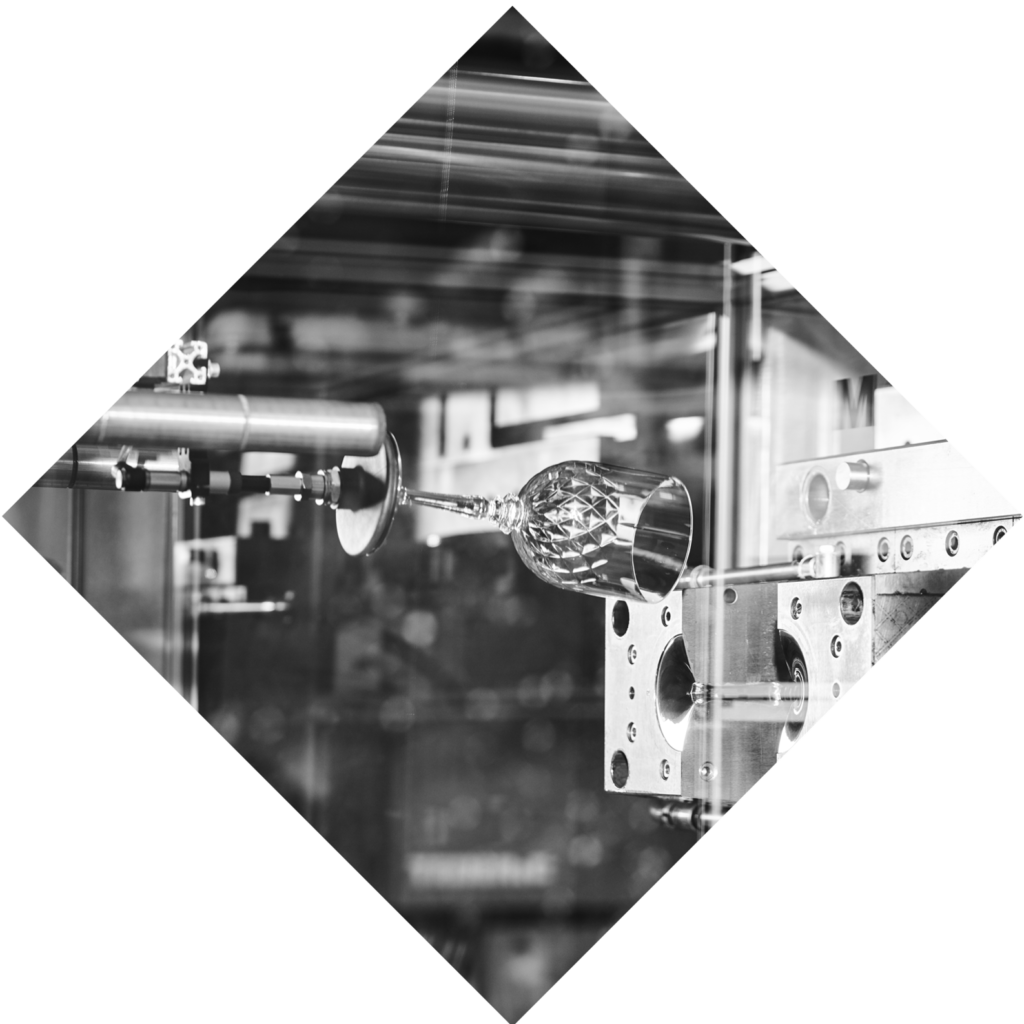

We have a team of highly qualified and dedicated professionals who are our most valuable resource, with know-how, skills, dedication and focus on finding new solutions and continuous improvements in the manufacture of moulds for plastic injection.

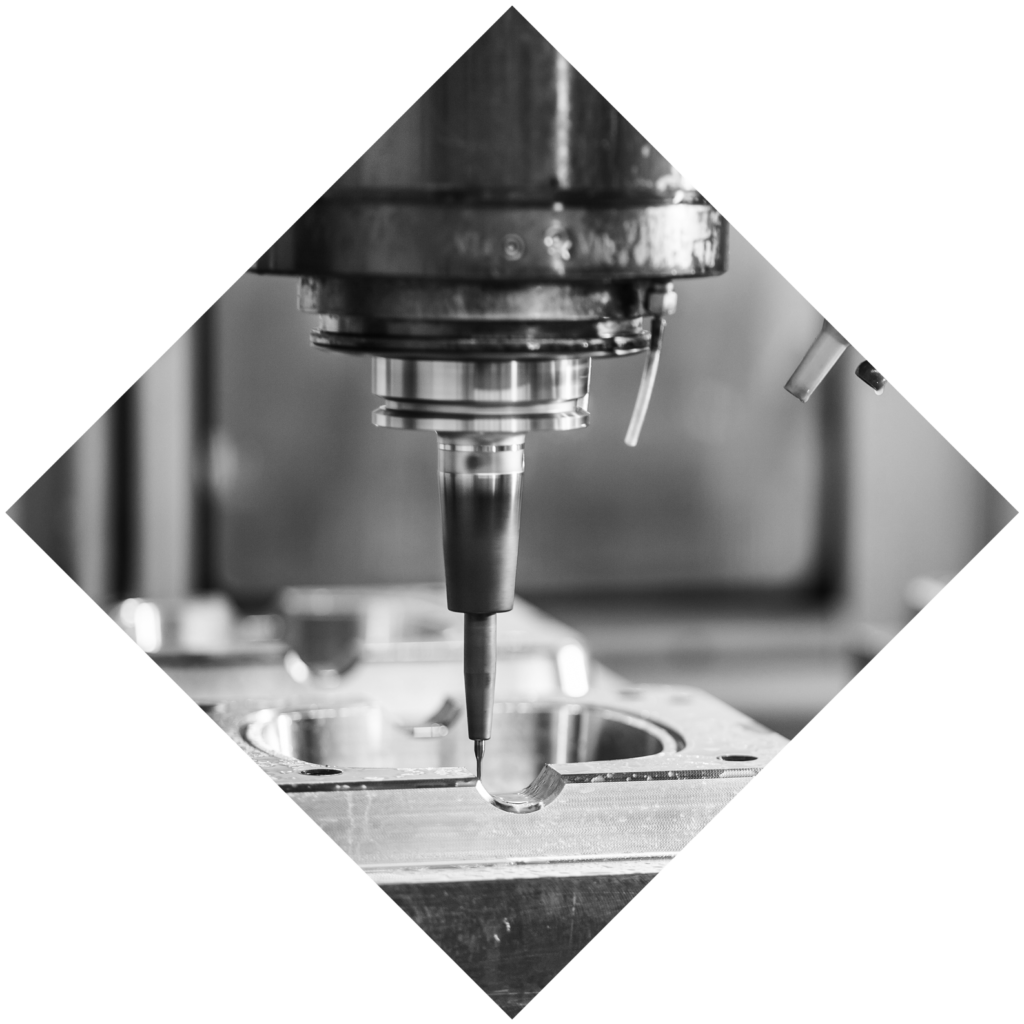

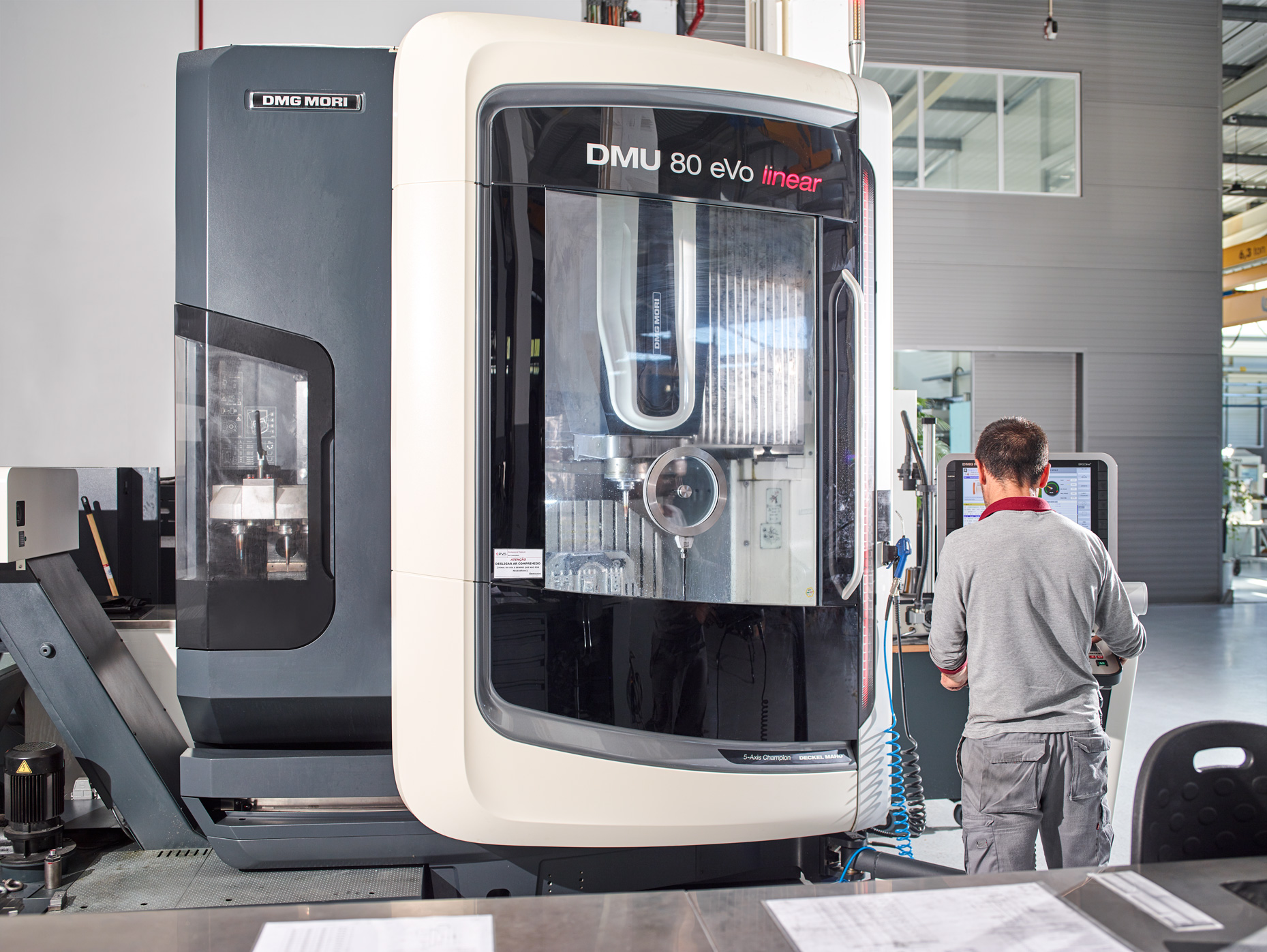

We have a machine park of the most technologically advanced equipment, from 3 axes, 4 axes and 5 axes, with an annual capacity of 160,000 hours available and with a maximum machining capacity of 3250X1700 mm, manufacturing moulds up to 35T.

We are permanently focused on providing a product of excellent quality with the best delivery times (between 10 to 14 weeks).