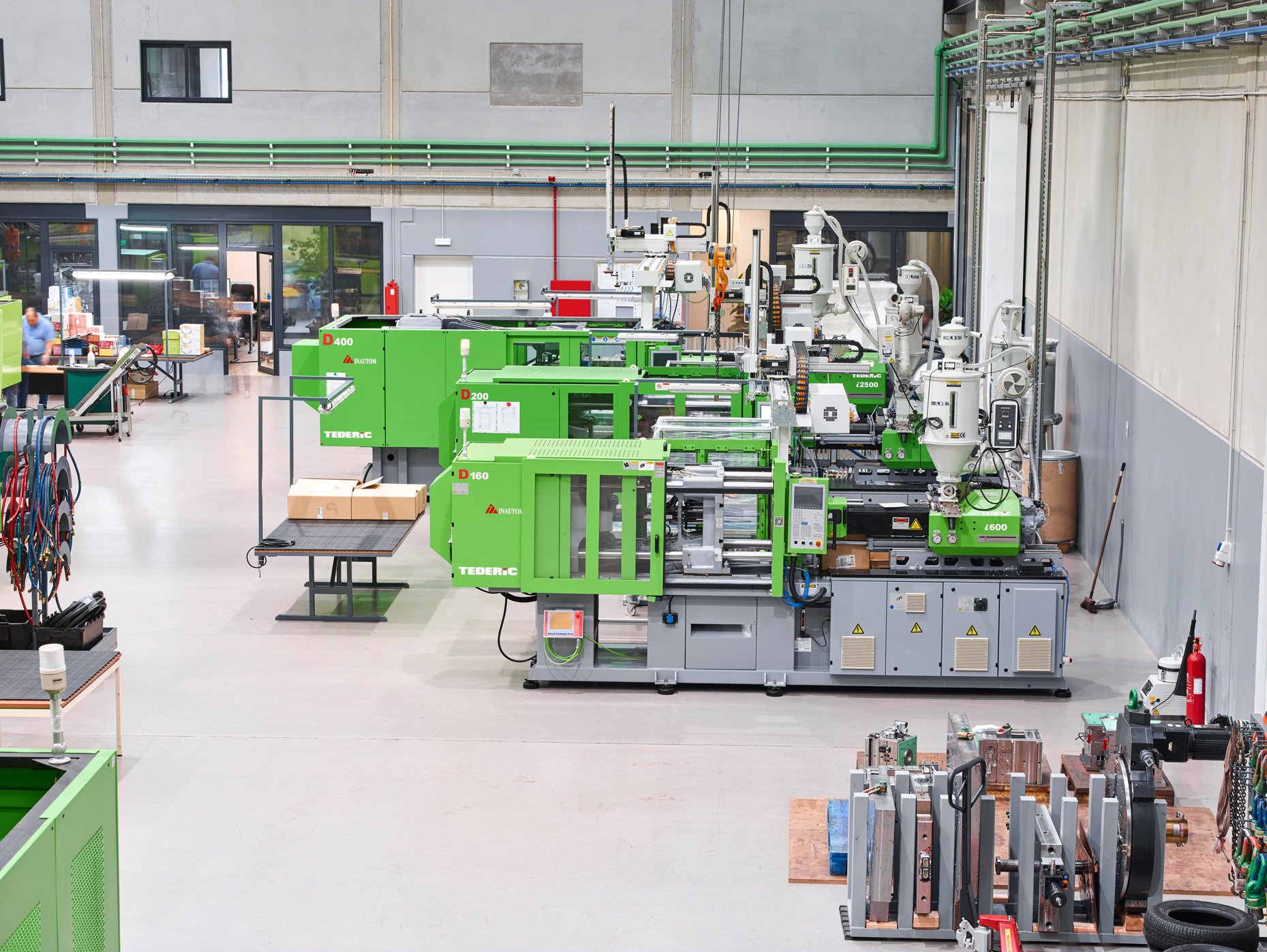

The modern facilities of MRS Plastics, a group company dedicated to the injection of plastics, have a total area of 2400 m2, being located next to PVS Moldes, which is why it is an advantage for our customers.

All plastic injection moulds are tested, and corrections / adjustments can be made in real time / on time when the test is performed. We also perform dimensional control of parts for later validation so that customers receive moulds ready for their series production.

A benefit of our company is the ability to, in addition to testing the moulds, produce small pre-series.

MRS Plastics is equipped with a complete range of injection machines with clamping forces that vary between 50T and 2000T, including 2 bi-material machines of 160T and 530T, both with rotating plate.

This capacity allows us to produce plastic parts ranging from 8 grams to 10 kilograms in any type of polymer that can be moulded by injection.

Among Which:

· ABS · ASA

· HIPS · HDPE

· LDPE · PA6, PA66

· PMMA · POM

· PP · PC

· PPS · PVC

· SAN · TPE´S

· Among Others

© 2020 PVS Portugal. All Rights Reserved. | General Terms and Conditions of Purchase | Designed by Blink Eye